Year after year, our computers and cell phones become more and more advanced thanks to the densification of their microelectronic components. This densification is the result of an always more effective miniaturization. Miniaturization is about to reach a technical limit due to the size of certain components which getting close to the size of a few atoms. The microelectronics industry is facing a physical barrier when it comes to increasing the integration density of components that could be overcome only through a disruptive innovation.

A solution could be found in 3D integration of microelectronics. Current microelectronic circuits are flat. Stacking their components one above the other would be a solution for further densification of circuits, improving their performances and reducing their energy consumption. New challenges then arise: connecting components to each other once they are stacked up. While their manufacturing and stacking are based on mature technologies, the making of vertical connections to bind them together and let the current flow remains complex. If current techniques in 3D microelectronics enable to design these high-density connections, alternative technologies are interesting to review.

Biologists and physicists from CEA, CNRS, UJF and Inra in Grenoble got the idea to take advantage of the extraordinary self-assembly capacity of certain biological compounds to let these connections build themselves on their own. In our cells, many complex and regular structures persistently assemble and disassemble. It is the case with the microfilament networks that constitute the skeleton of cells (cytoskeleton). These microfilaments are mainly composed of actin

[1]. They interact with one another to form braids, bundles, layers, and columns the architecture and mechanical properties of which regulate and control the shape of cells. The formation of these superstructures obey to mechanical and geometrical laws which are studied and mastered by a team of the Laboratory of Plant and Cell Physiology

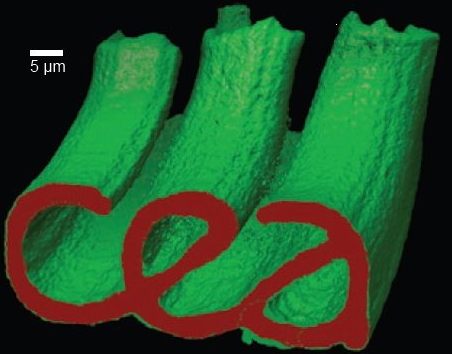

[2]. The researchers have developed a technique which enables them to control the self-assembly of actin microfilaments in 3D between two glass plates. Thanks to the technologies developed at the Laboratory of Microelectronics Technologies (CNRS/UJF) and Leti (CEA), the glass plates were placed 30 microns away from each other and micro-structured with a laser beam. Researchers then injected between the two surfaces a solution containing actin monomers that polymerized in response to the geometry of the microstructures. Actin columns of controlled shape and size thus self-assembled from the two surfaces and met to establish connections. In the same way, researchers succeeded in making columns grow from a surface. Each column entered the hollow cylinder formed from the other, in the manner of an outlet and a plug. These connections were then coated with gold nanoparticles, enabling electric current to flow between the two surfaces.

| |

|

| | |

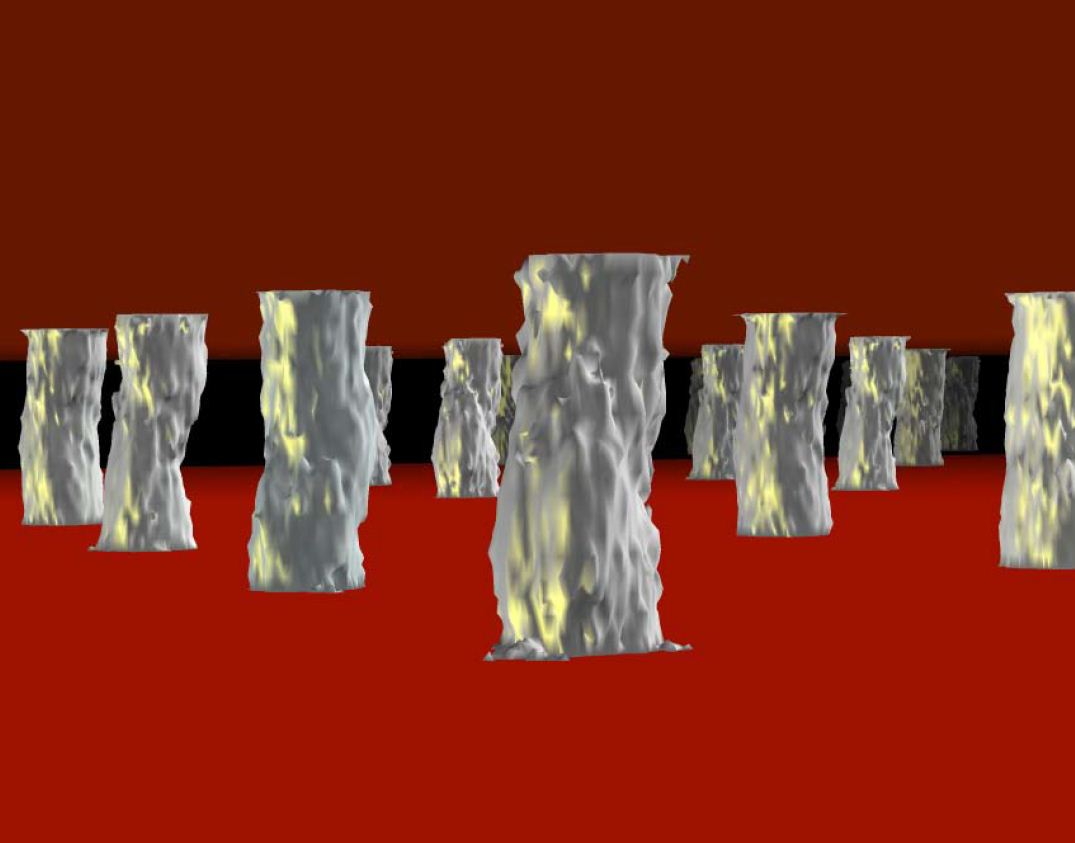

3D visualization of a network of connections made from actin micropillars (gray)

©CEA/R.Galland | |

3D visualization of an actin network (green) assembled from a micropatterned surface displaying the CEA logo (red). |

These results show that this self-assembly process used by actin microfilaments can have industrial applications and can be a source of inspiration for engineering processes in many fields, even the most unexpected ones.

[1] Actin: protein which constitutes the skeleton of living cells and enables to regulate and control their shapes.

[2]

Laboratory of the Institute for Research in Life Sciences and Technologies (CEA/CNRS/UJF/INRA)